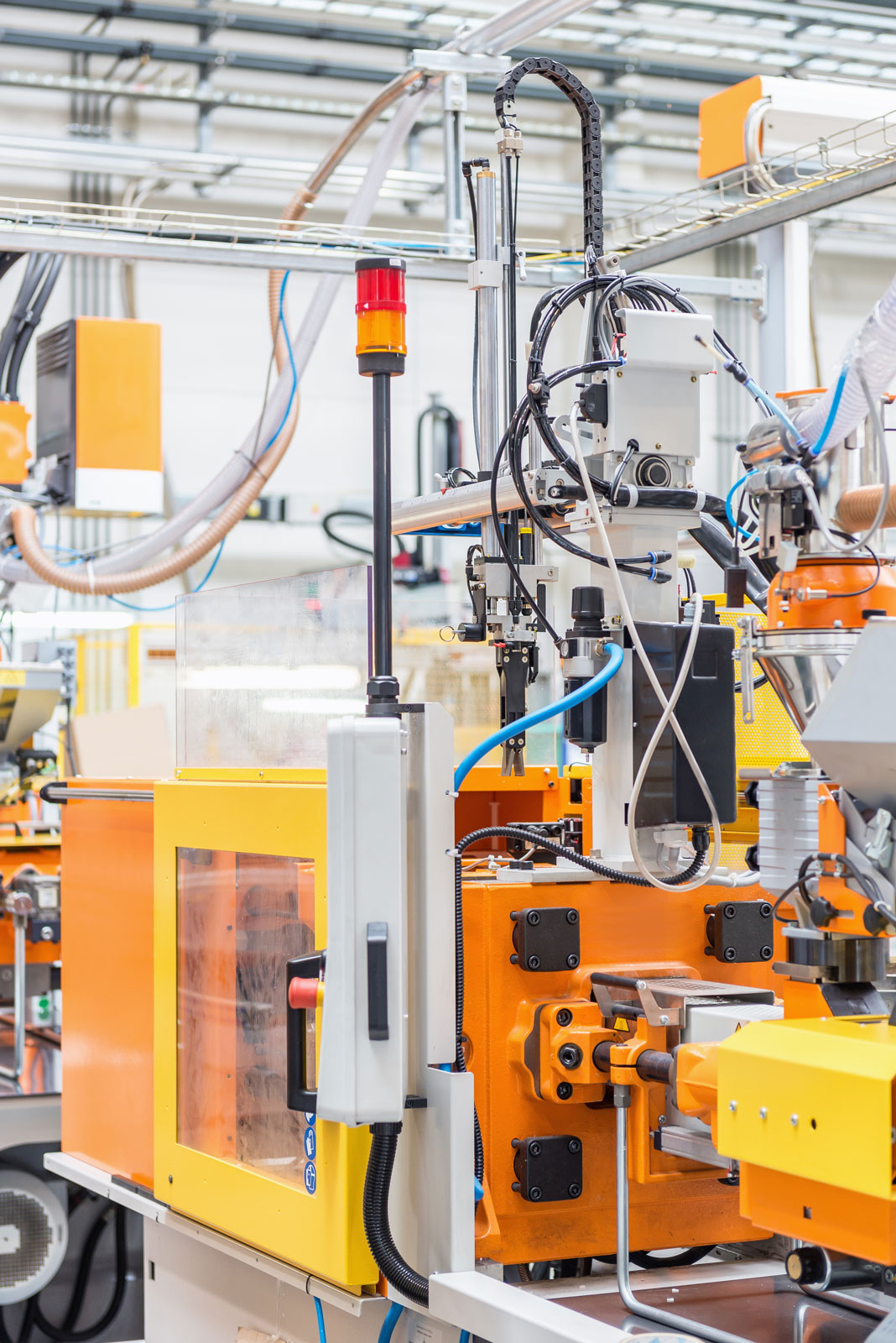

Custom Injection Molding

INJECTION MOLDING WITH PENINSULA PLASTICS

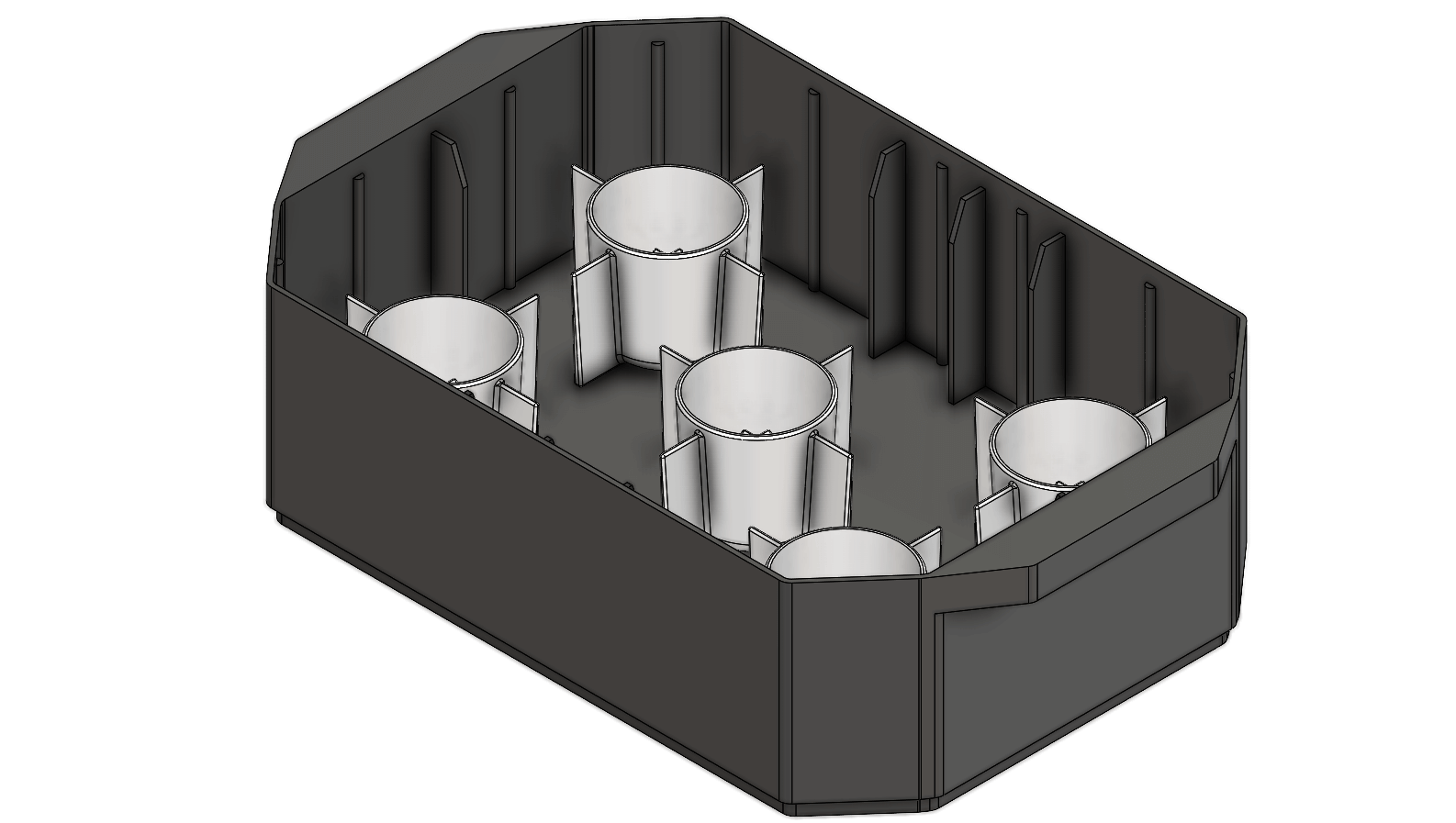

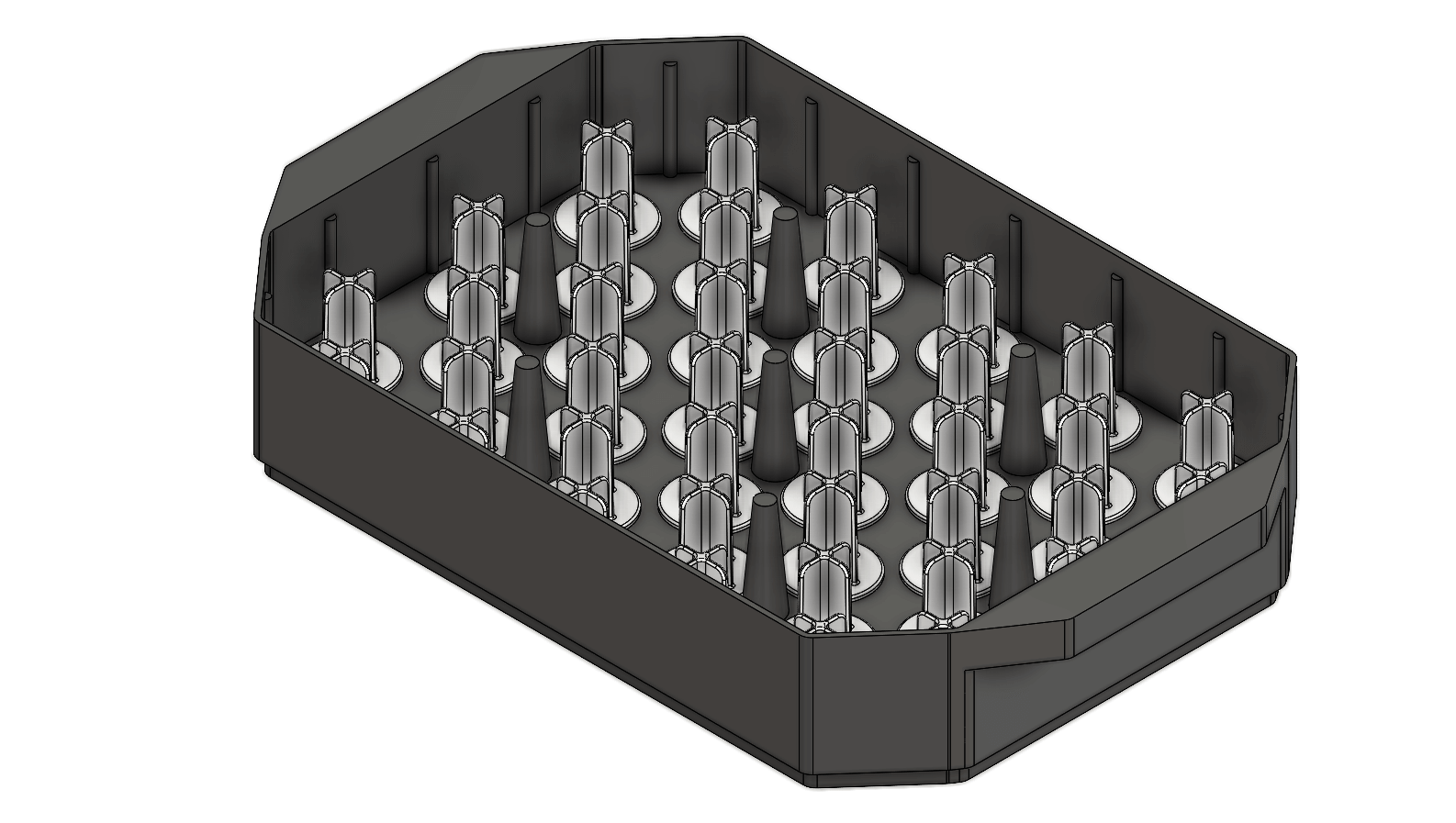

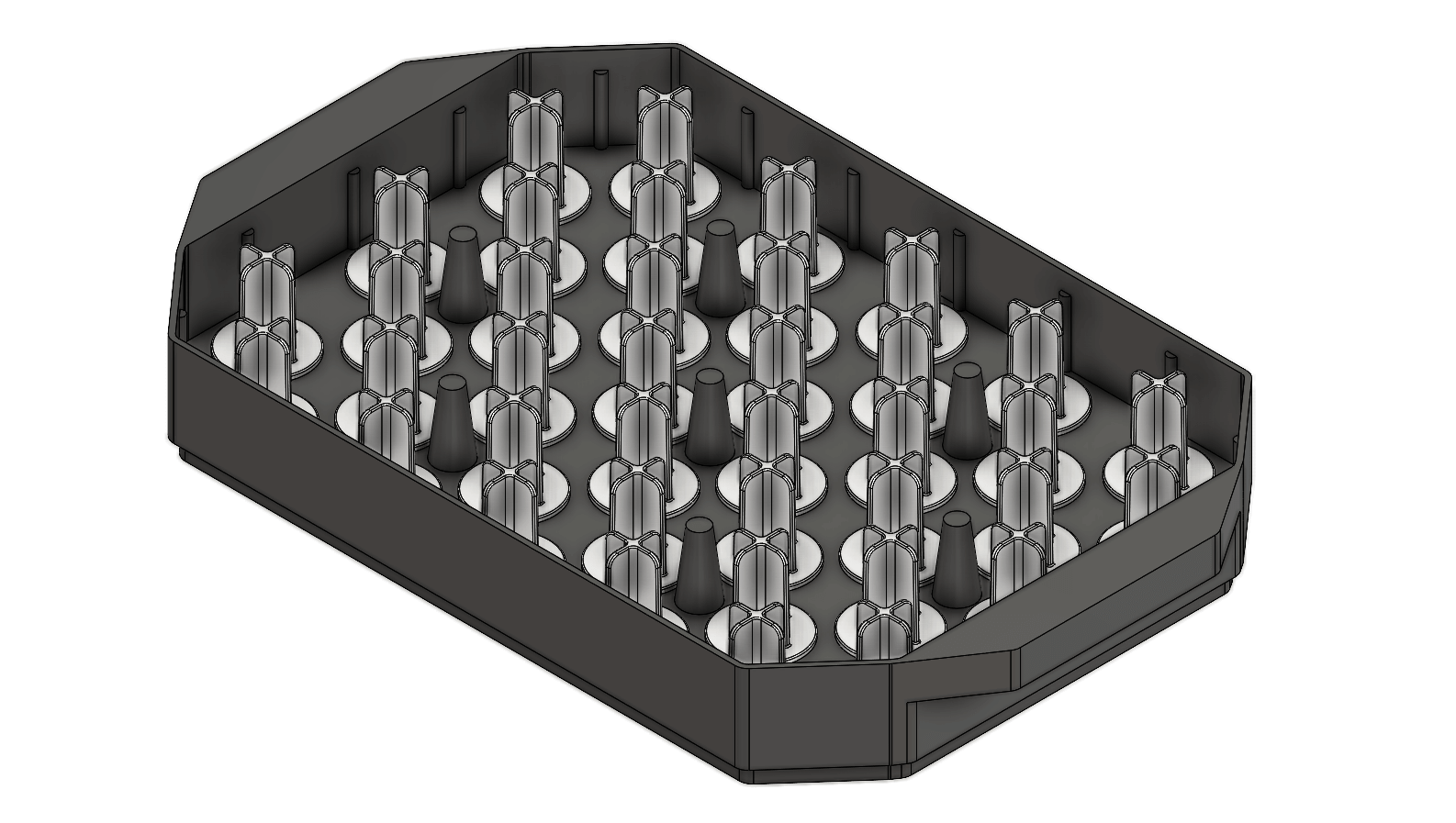

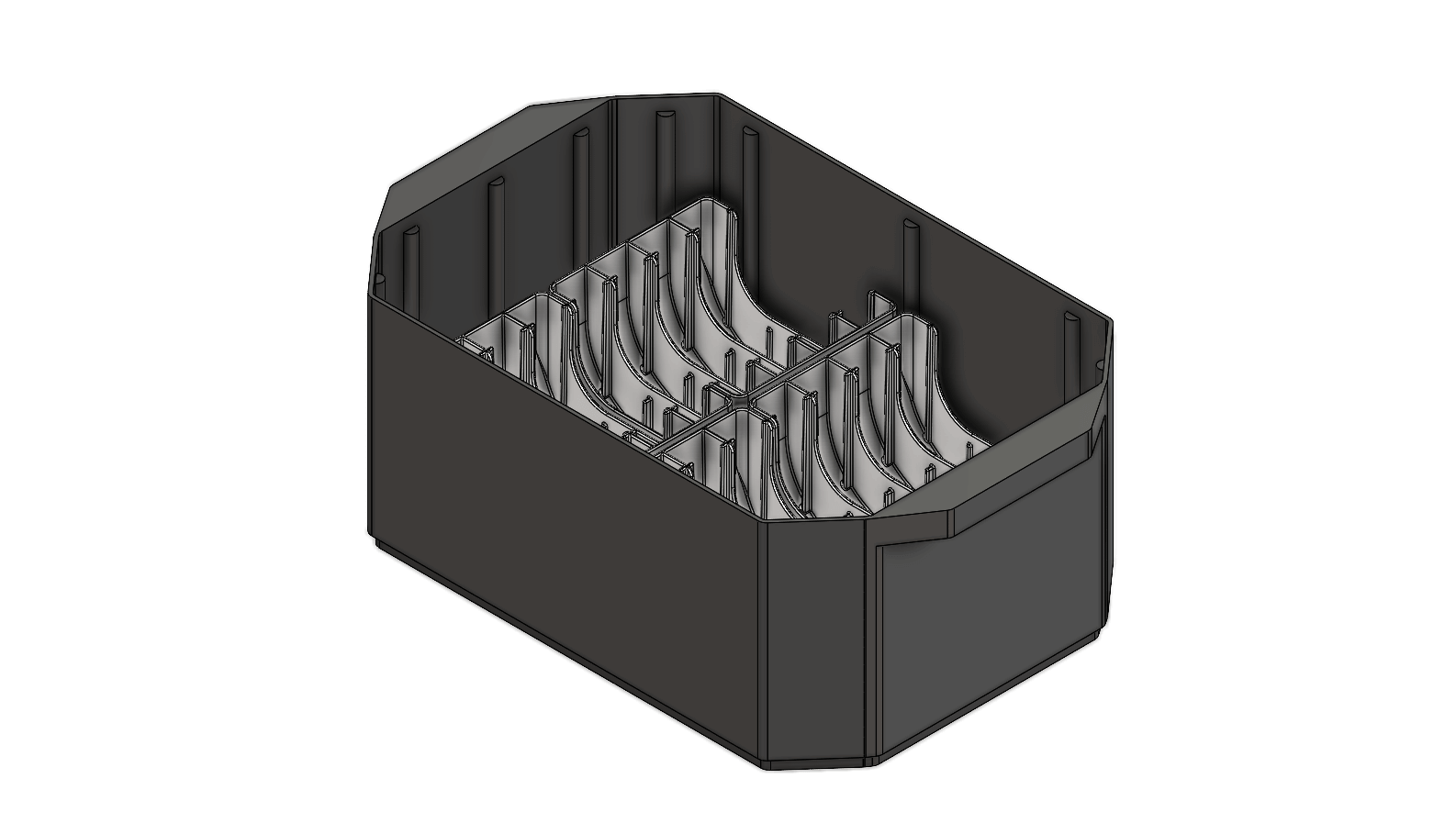

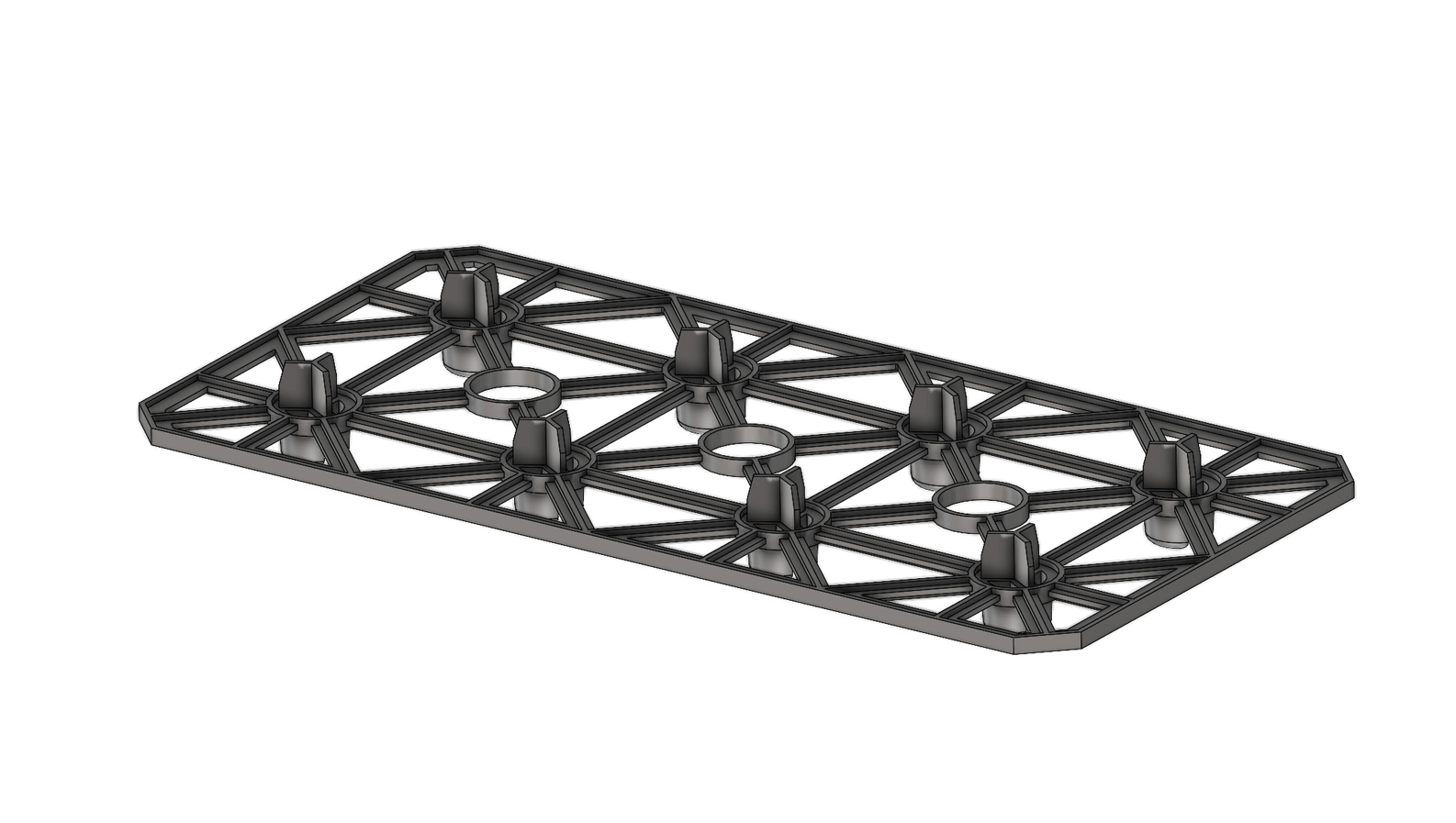

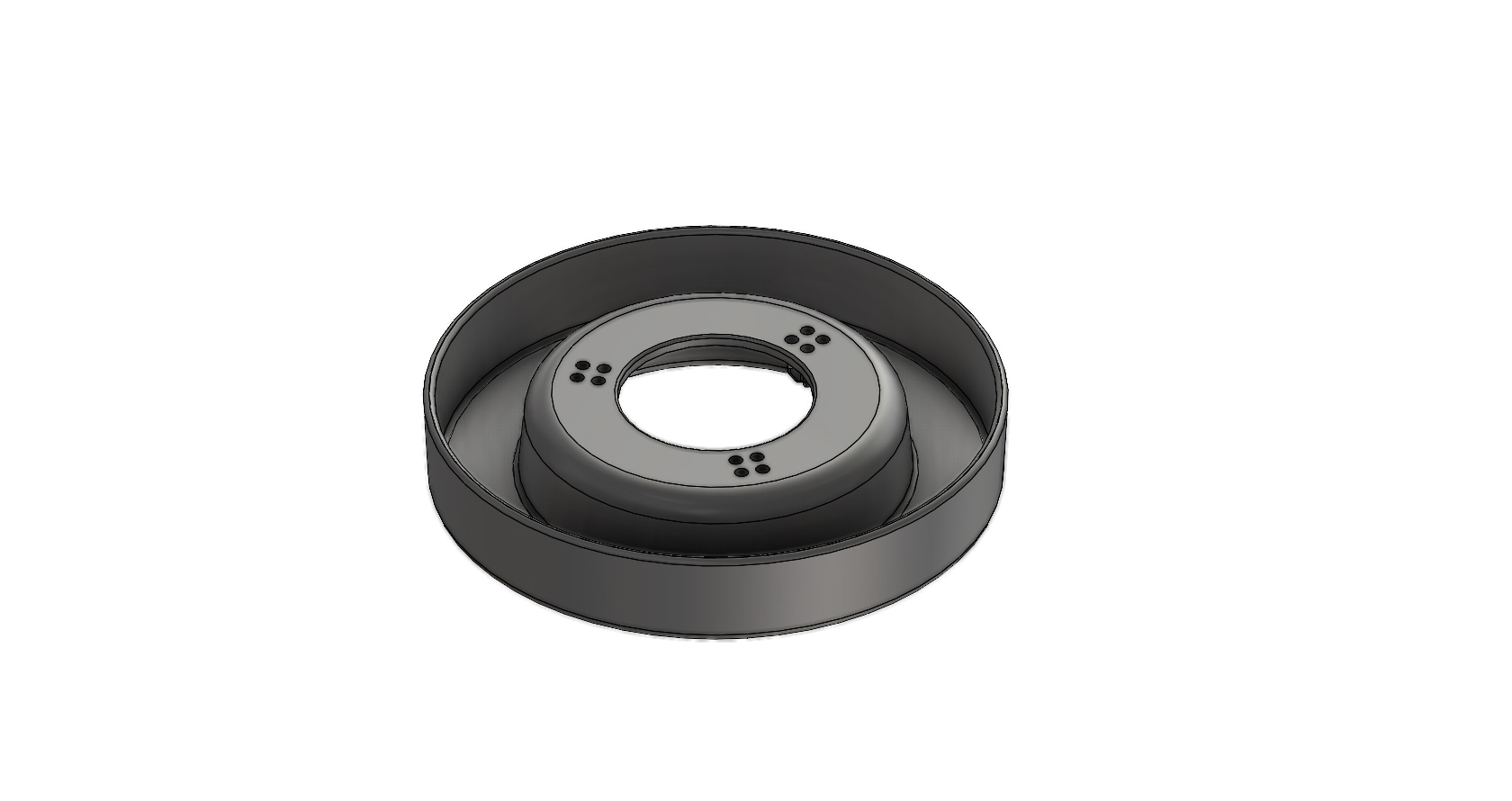

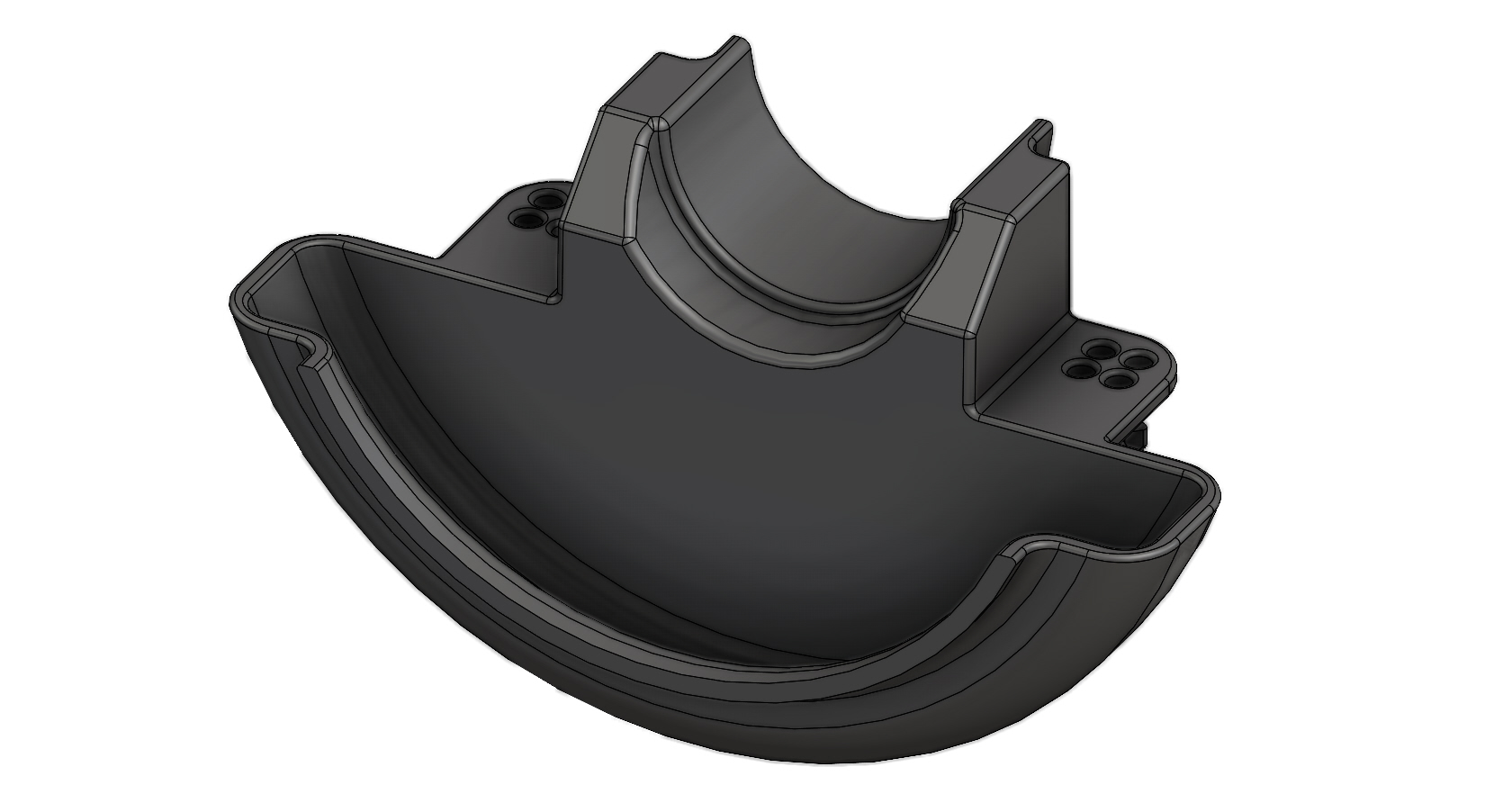

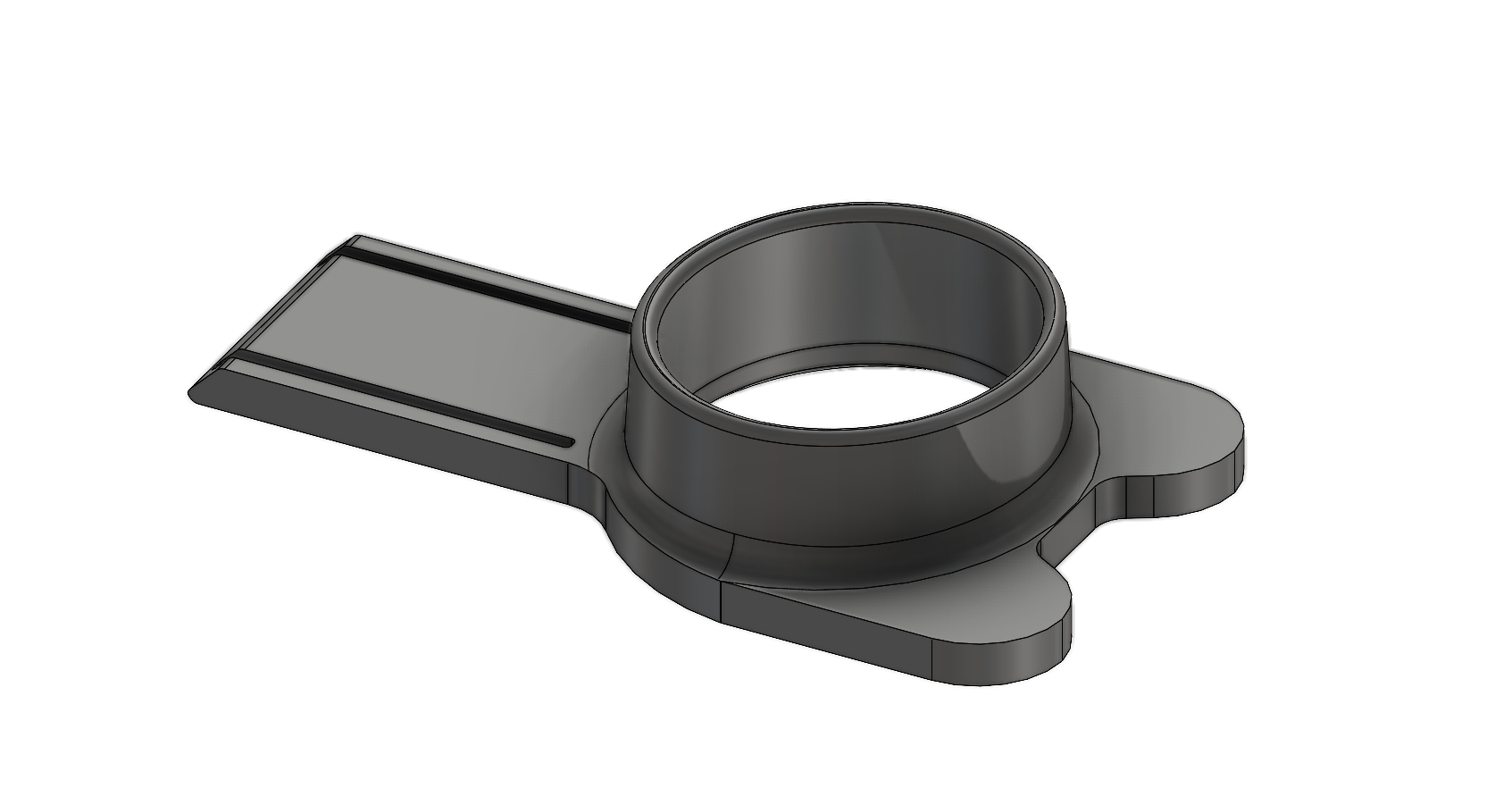

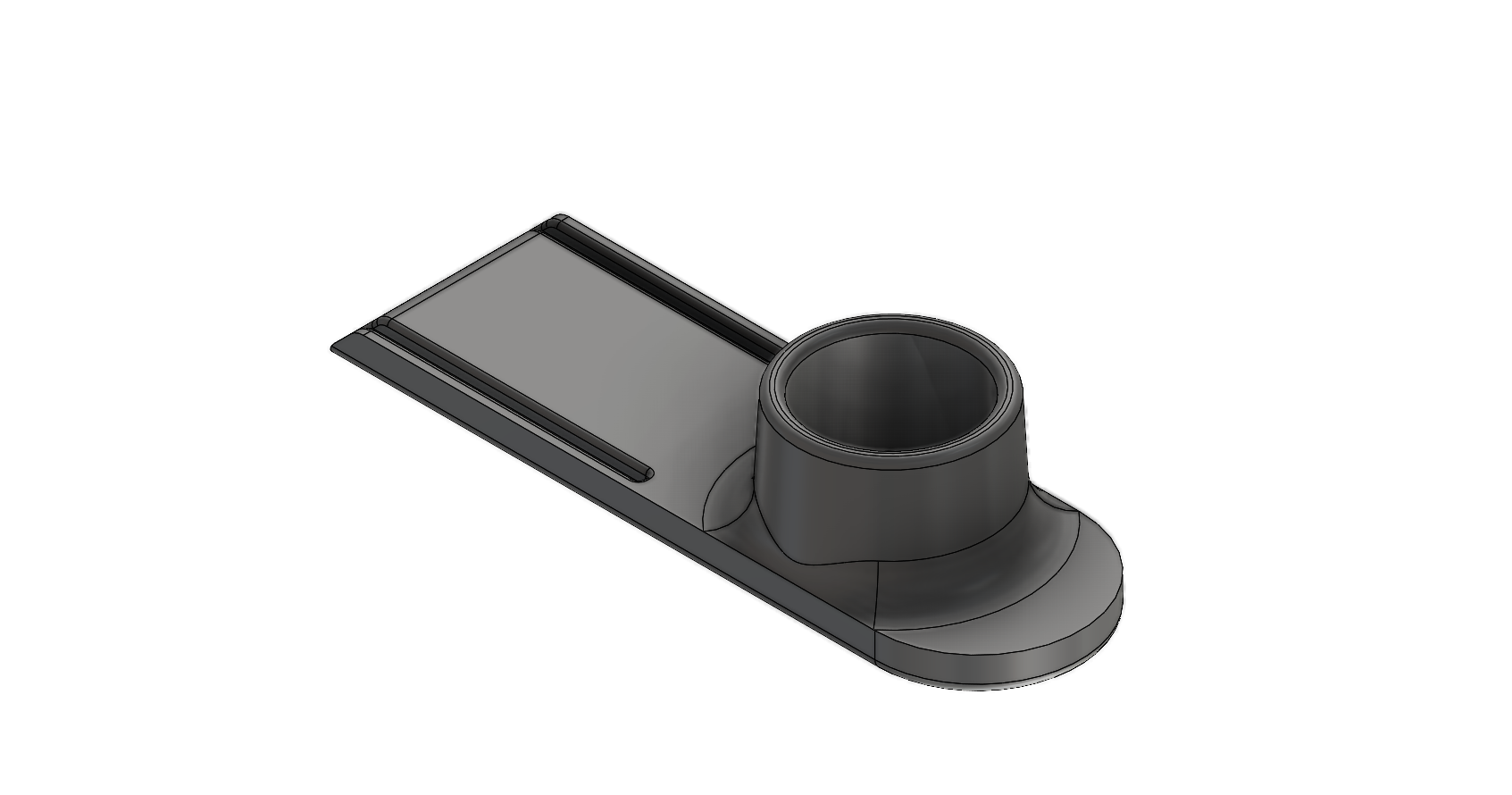

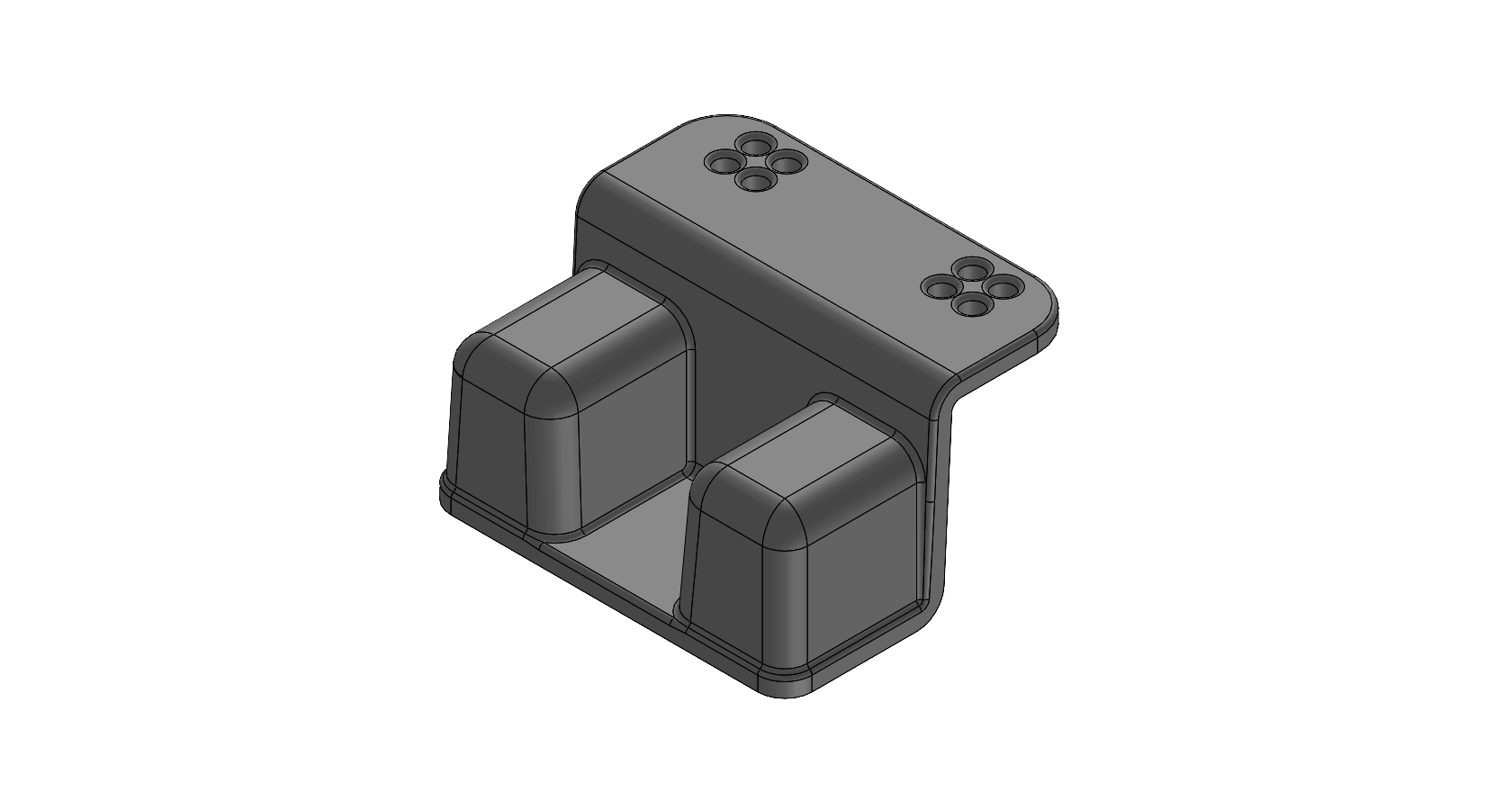

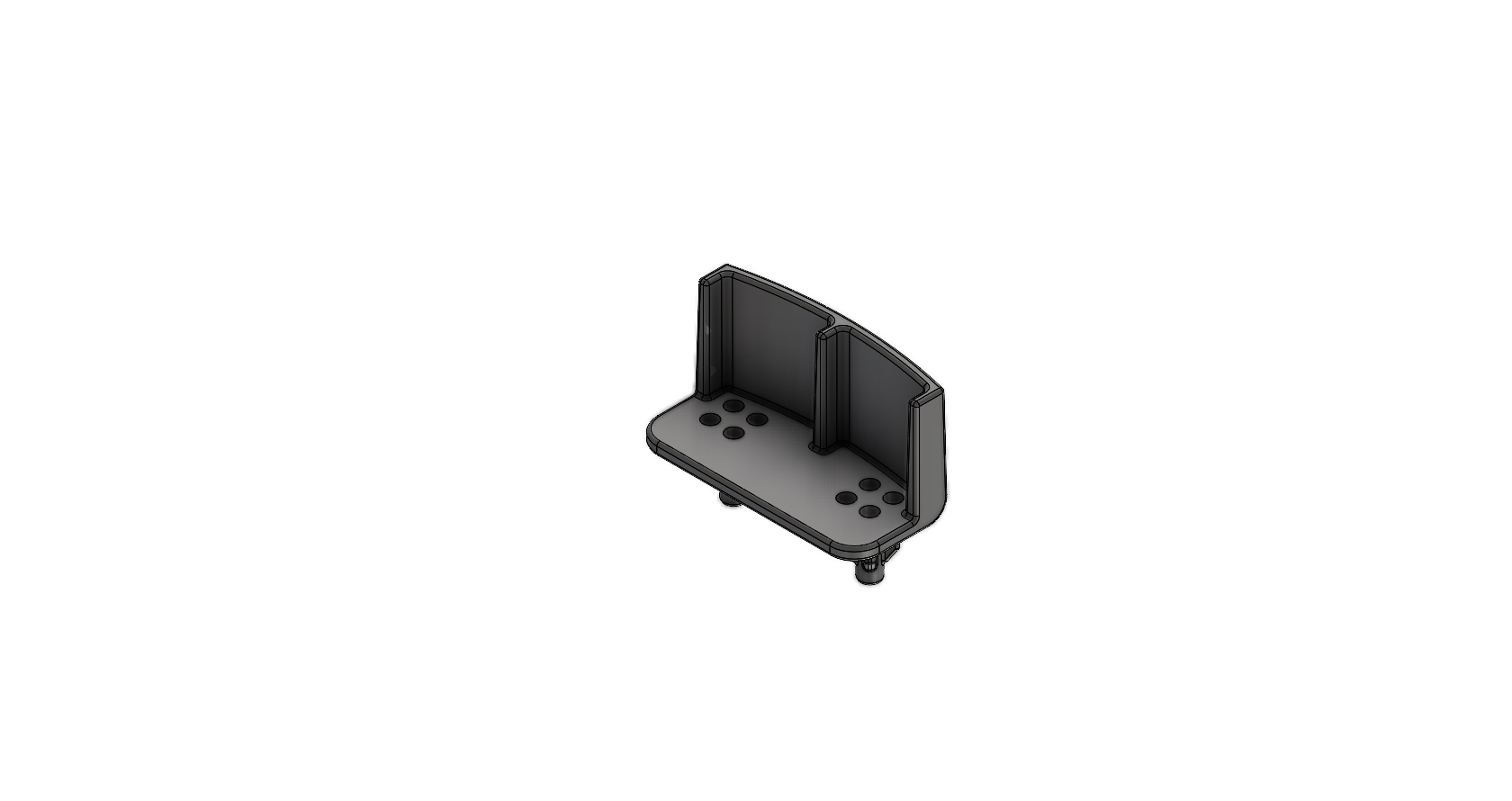

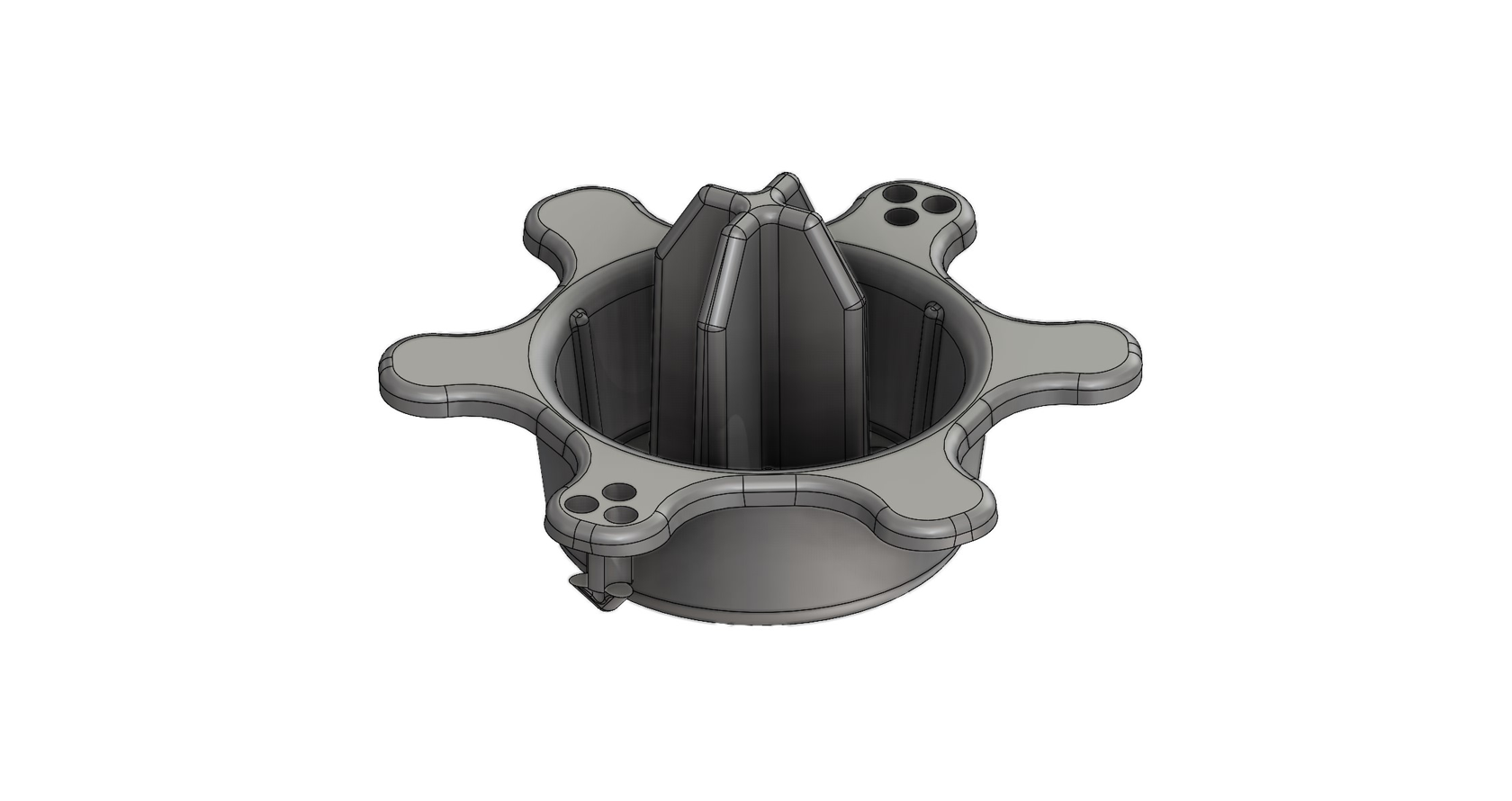

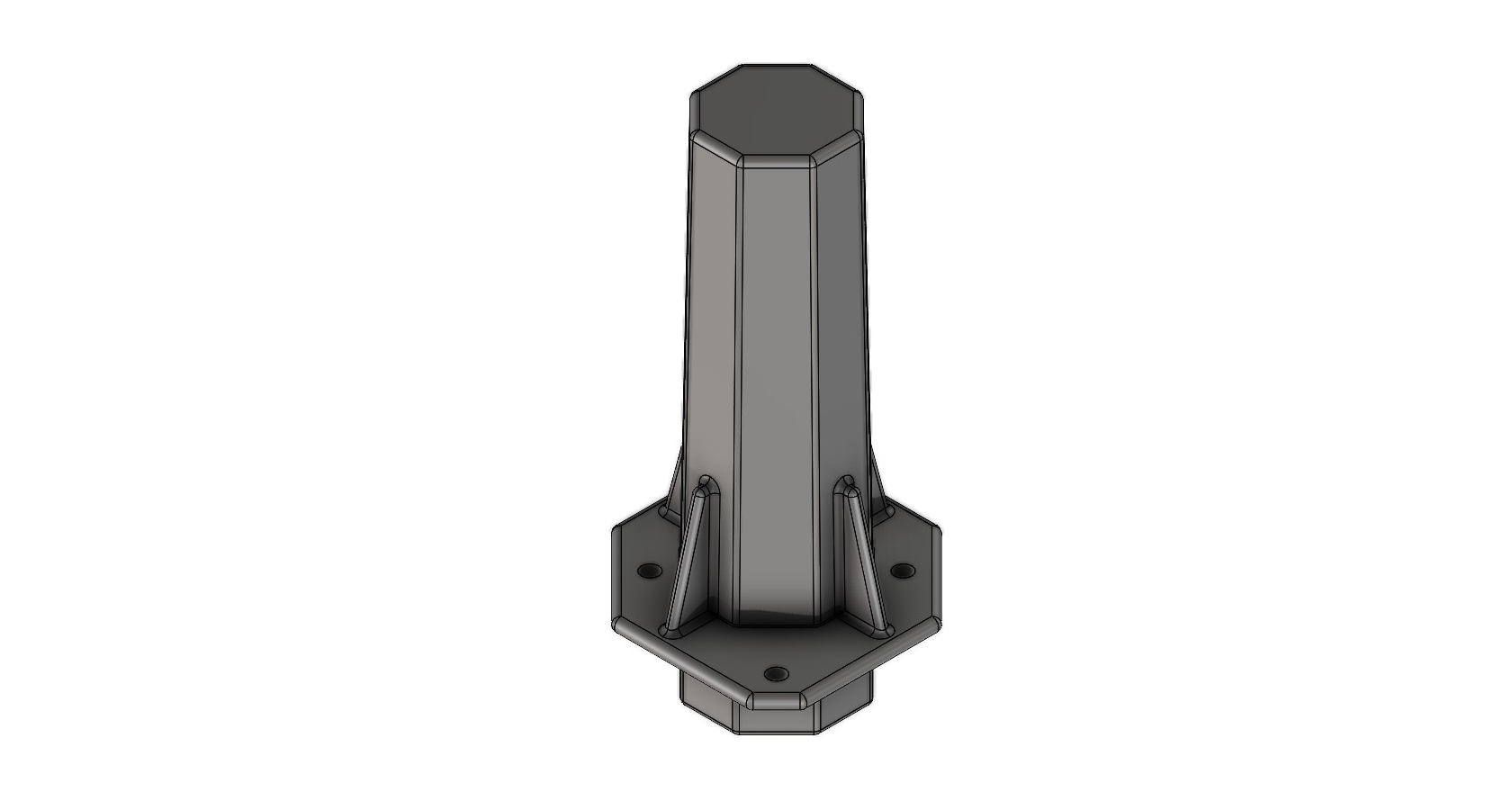

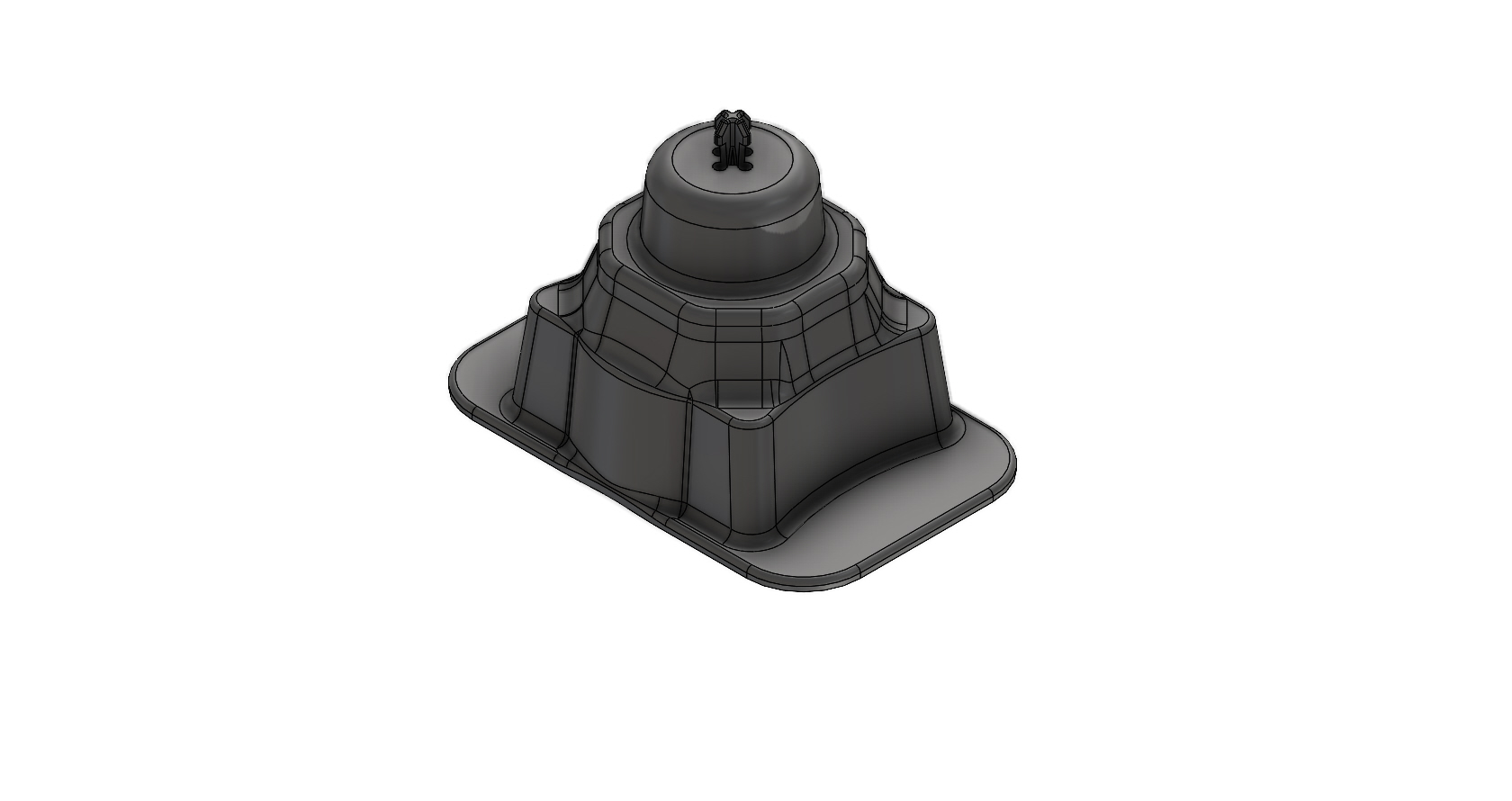

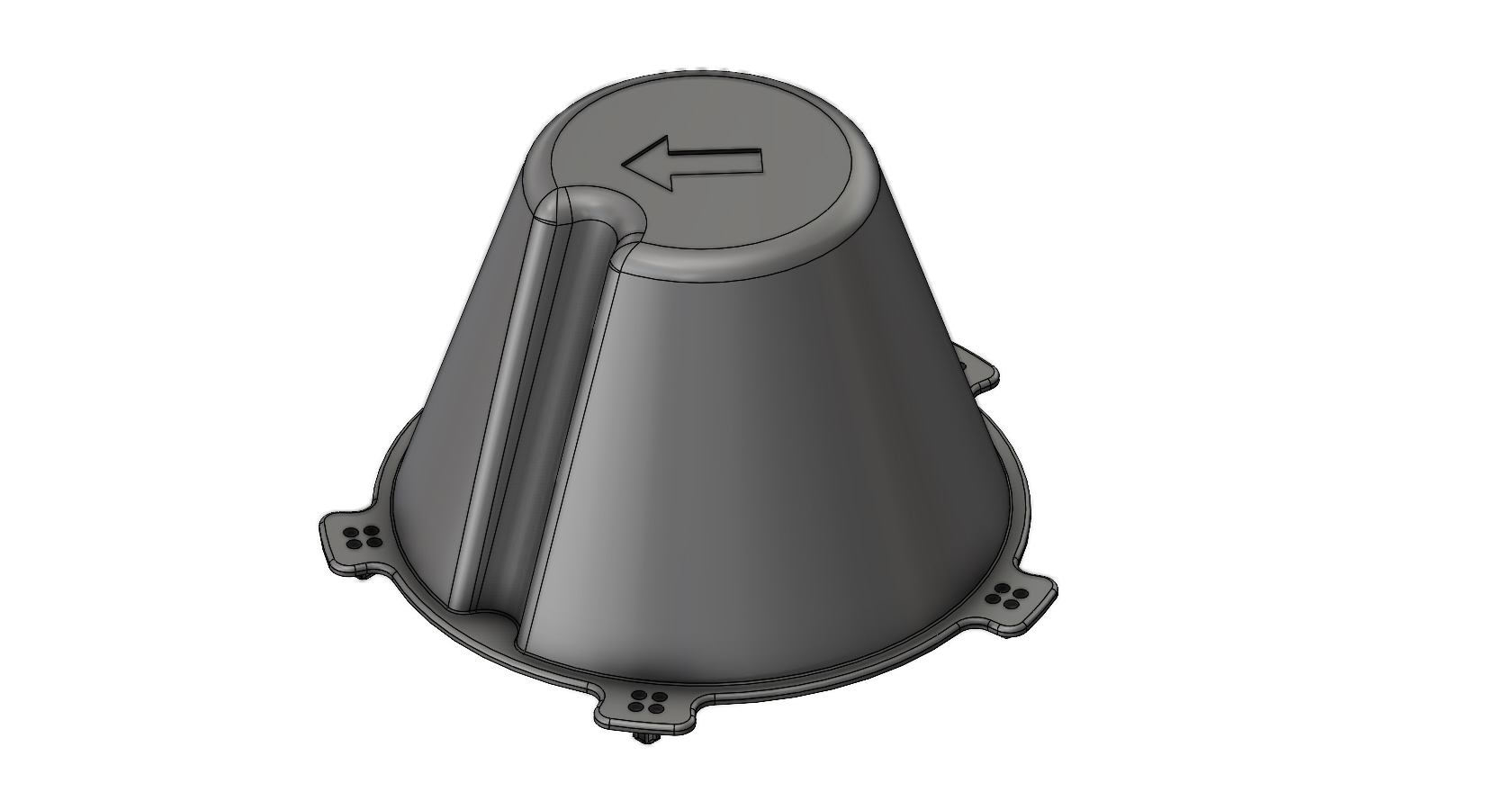

Injection molded inserts created at Peninsula Plastics are installed into containers, trays, pallets, and lids to enhance structure and support securing components. Additionally, add-on inserts improve ergonomics, enhance the ability for trays to nest, and increase visibility when used in conjunction with robot vision systems. Inserts are produced using a variety of materials, based on the specific application need.

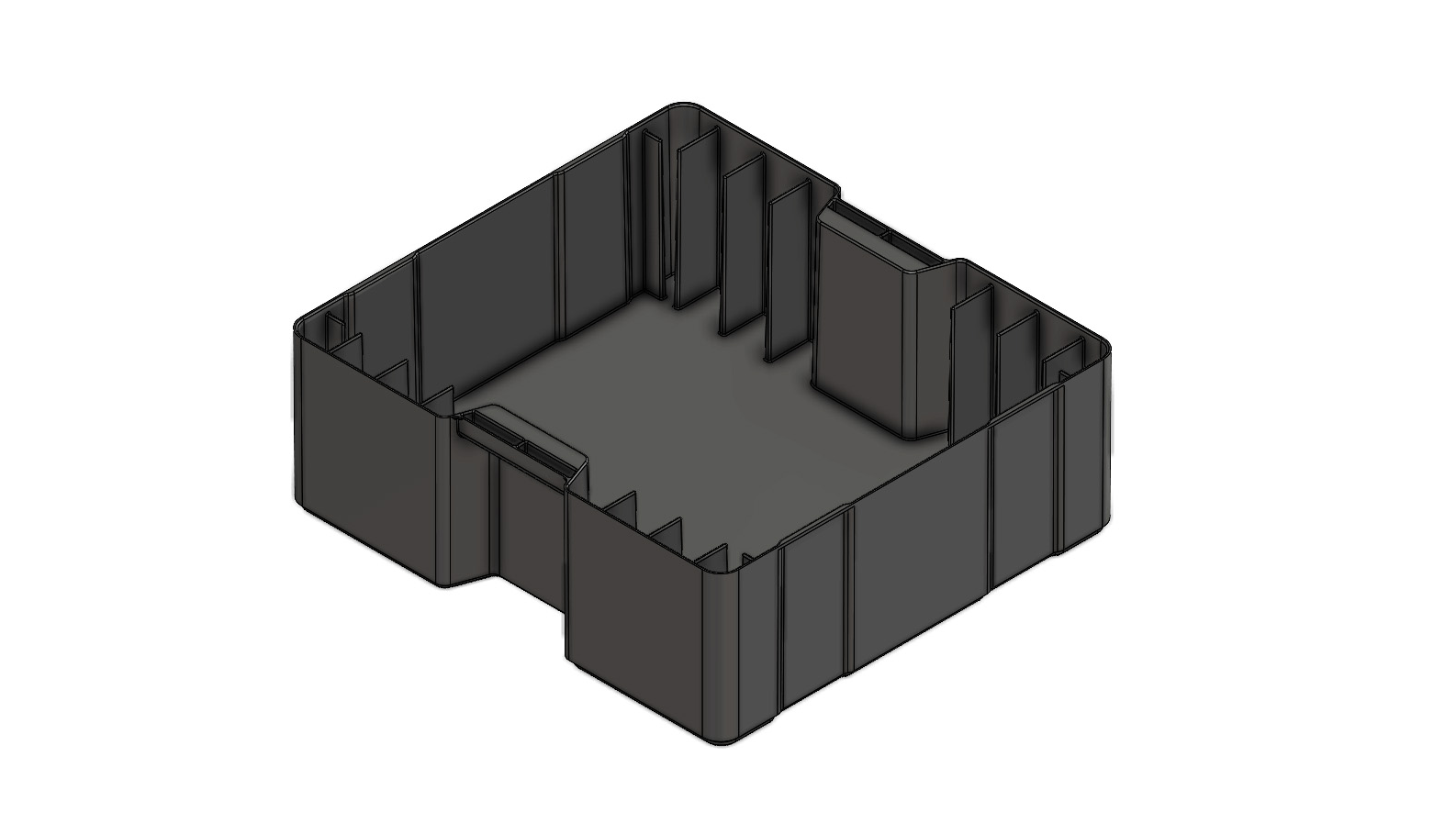

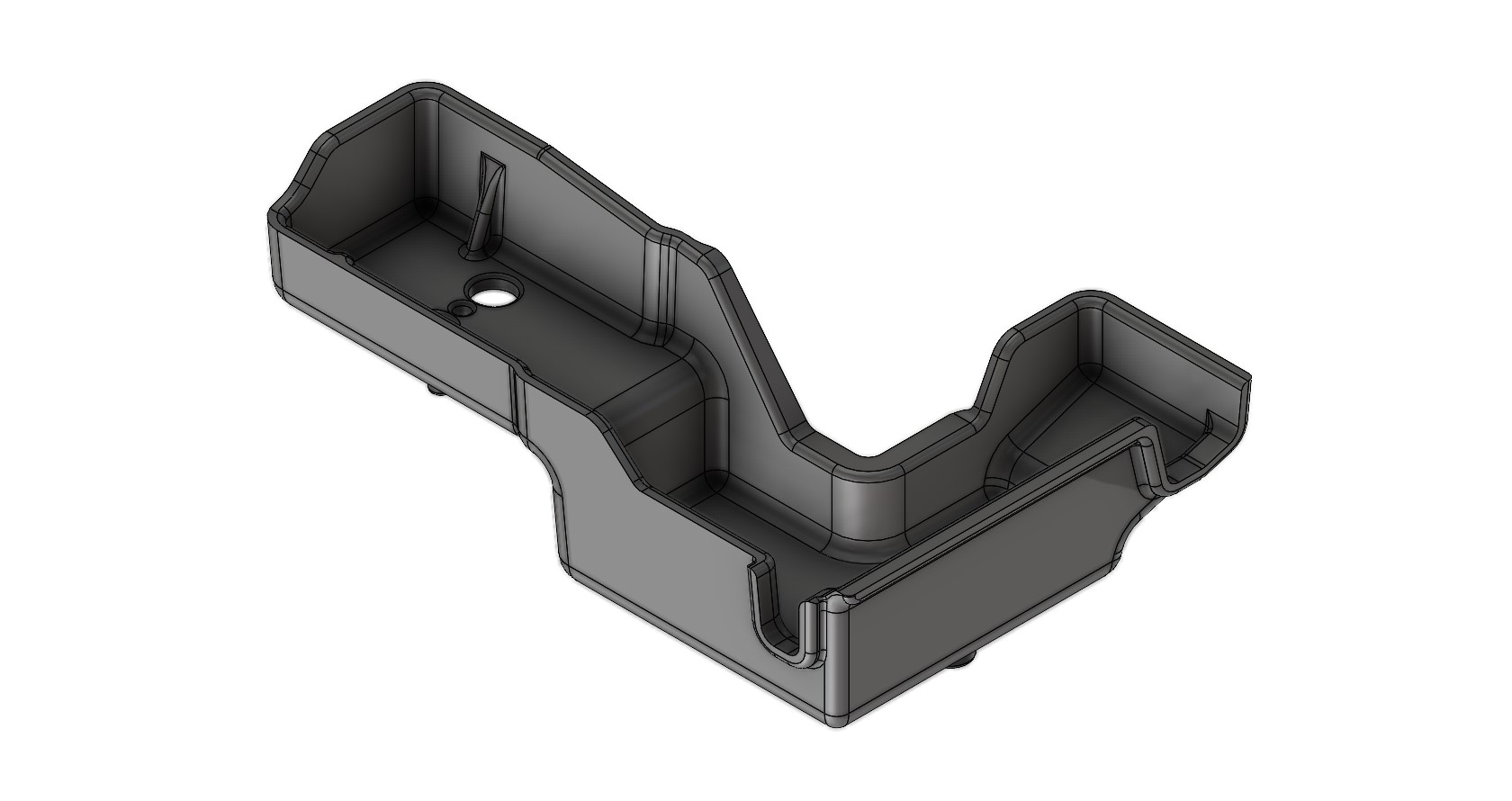

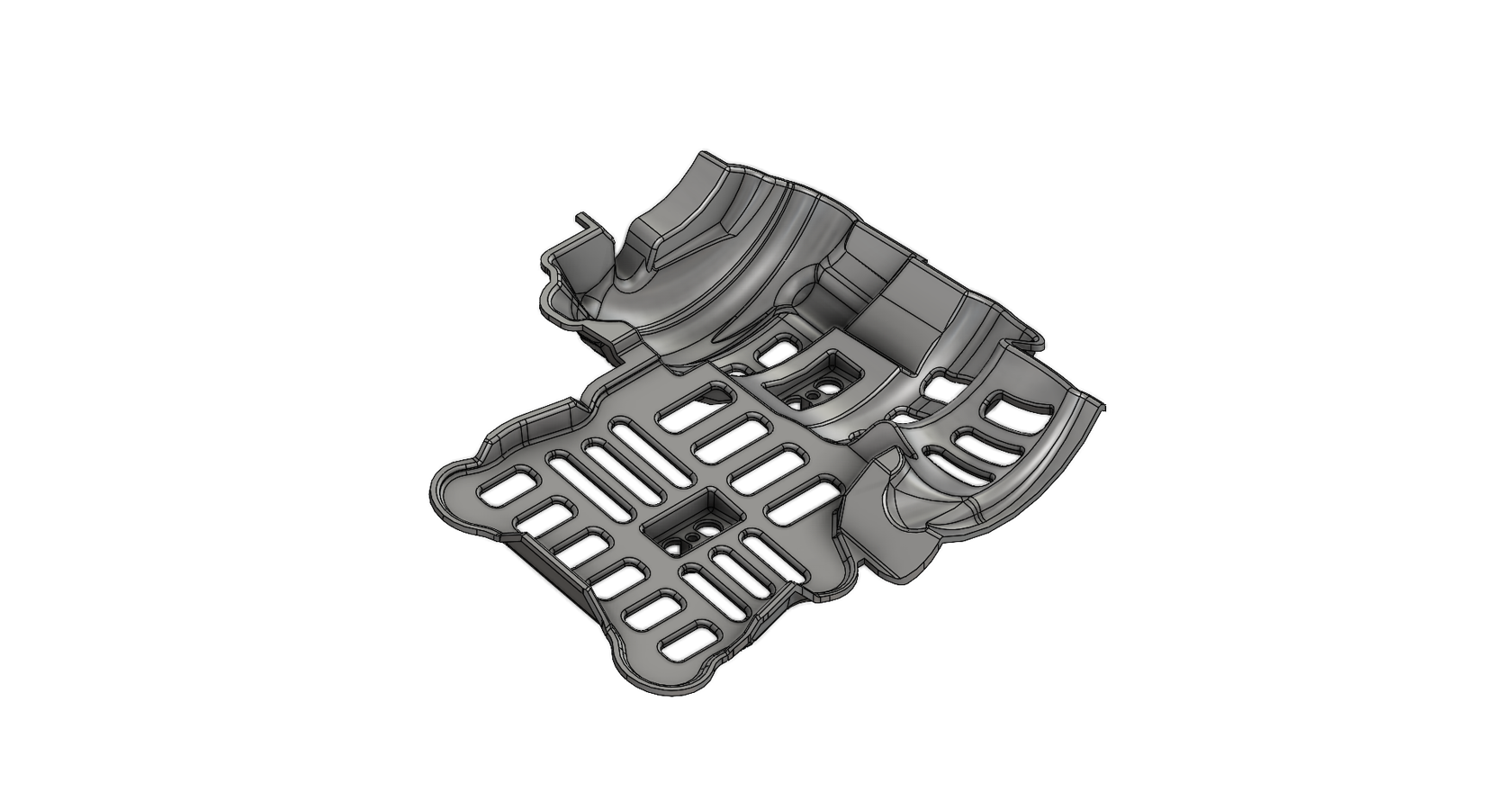

Peninsula Plastics’ injection molding capabilities don’t stop at inserts and add-ons, we also produce custom injection molded trays and totes. Trays and totes are produced for products that demand precise packaging geometries due to intricate characteristics. Our technical engineering team bases designs on accurate part capture and high-precision formability to support quality and consistency.

THE FLEXIBILITY OF INJECTION MOLDING

Peninsula Plastics recognizes the importance of safeguarding your goods at their most vulnerable moments during transportation and storage. Some packaging solutions require a unique form of protection only offered through a specific combination of design input and material selection.

MATERIAL SELECTION: THERMOPLASTIC POLYURETHANE (TPU)

- Resistant to abrasion.

- Excellent flexibility.

- Remarkable shock absorption properties.

MATERIAL SELECTION: HIGH-DENSITY POLYETHYLENE (HDPE)

- High resistance to impact.

- Very durable and lightweight.

- Anti-corrosive properties.

MATERIAL SELECTION: POLYPROPYLENE (PP)

- Rugged and resistant thermoplastic.

- Supports structure strength and stability.

MATERIAL SELECTION: ACRYLONITRILE BUTADIENE STYRENE (ABS)

- Corrosion resistant.

- High tensile strength.

- Great impact resistance and shock absorption.

Injection Molded Totes & Trays

LOOKING FOR A HIGH-PRECISION INJECTION MOLDED TRAY OR TOTE?

Peninsula Plastics injection molded trays and totes support complex components that demand precision.

Injection Molded Inserts

1.50″ Button

2.25″ Narrow Cup

4.30″ Round Cup

5.50″ Round Cup

7.60″ Round Cup

7.70″ Round Cup

Half Round Cup

Inverted Round Cup

Round Cup

Wide Cup

Inverted Complex Ring

Inverted Ring

Ring

Ergo Side Lock

Hook

Slide Lock

4.00″ Bungee

Bracket

Clutch Detail

Extended Bracket

Knit Stack Detail

L-Shape Bracket 1.0

L-Shape Bracket 2.0

L-Shape Bracket 3.0

Pinion Gear Holder

Pinion Output Carrier

Oil Pump Case 1.0

Oil Pump Case 2.0

Oil Pump Case 3.0

Part Cradle

Flipper

Stack Post

Differential Case

Part Cover

Part Support

Cold Plate

NEED A CUSTOM INSERT ADDED TO YOUR SOLUTION?

Injection molded add-ons offer an unbeatable combination of support and protection.